Rapid COVID-19 tests are on the rise to deliver results faster to more people, and scientists need an easy, foolproof way to know that these tests work correctly and the results can be trusted. Nanoparticles that pass detection as the novel coronavirus could be just the ticket.

Such coronavirus-like nanoparticles, developed by nanoengineers at the University of California San Diego, would serve as something called a positive control for COVID-19 tests. Positive controls are samples that always test positive. They are run and analyzed right alongside patient samples to verify that COVID-19 tests are working consistently and as intended.

The positive controls developed at UC San Diego offer several advantages over the ones currently used in COVID-19 testing: they do not need to be kept cold; they are easy to manufacture; they can be included in the entire testing process from start to finish, just like a patient sample; and because they are not actual virus samples from COVID-19 patients, they do not pose a risk of infection to the people running the tests.

Researchers led by Nicole Steinmetz, a professor of nanoengineering at UC San Diego, published their work in the journal Biomacromolecules.

This work builds on an earlier version of the positive controls that Steinmetz’s lab developed for the RT-PCR test, which is the gold standard for COVID-19 testing. The positive controls in the new study can be used not only for the RT-PCR test, but also for a cheaper, simpler and faster test called the RT-LAMP test, which can be done on the spot and provide results in about an hour.

Having a hardy tool to ensure these tests are running accurately—especially for low-tech diagnostic assays like the RT-LAMP—is critical, Steinmetz said. It could help enable rapid, mass testing of COVID-19 in low-resource, underserved areas and other places that do not have access to sophisticated testing equipment, specialized reagents and trained professionals.

Upgraded positive controls

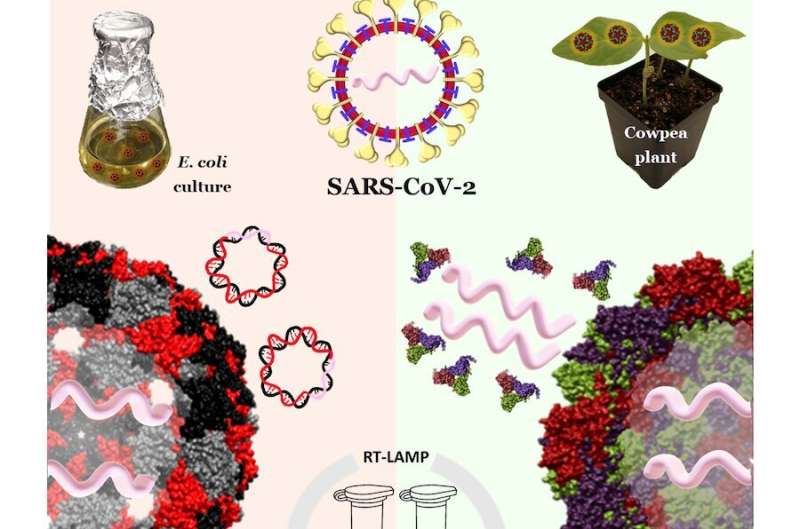

The new positive controls are essentially tiny virus shells—made of either plant virus or bacteriophage—that house segments of coronavirus RNA inside. The RNA segments include binding sites for both of the primers used in the PCR and LAMP tests.

“This design creates an all-in-one control that can be used for either one of these assays, making it very versatile,” said first author Soo Khim Chan, who is a postdoctoral researcher in Steinmetz’s lab.

The team developed two types of positive controls. One was made from plant virus nanoparticles. To make them, the researchers infected cowpea plants in the lab with cowpea chlorotic mottle virus and then extracted the viruses from the plants. Afterwards, the researchers removed the virus’ RNA and replaced it with a custom-made RNA template containing specific yet non-infectious sequences from the SARS-CoV-2 virus. The resulting nanoparticles consist of coronavirus RNA sequences packaged inside plant virus shells.

The other positive control was made from bacteriophage nanoparticles. It involved a similar recipe. The researchers infected E. coli bacteria with custom-made plasmids—rings of DNA—that contain specific fragments of sequences (which are also non-infectious) from the SARS-CoV-2 virus, as well as genes coding for surface proteins of a bacteriophage called Qbeta. This process caused the bacteria to produce nanoparticles that consist of coronavirus RNA sequences packaged inside bacteriophage shells.

The plant virus and bacteriophage shells are key to making these positive controls so sturdy. They protect the coronavirus RNA segments from breaking down at warmer temperatures—tests showed that they can be stored for a week at temperatures up to 40 C (104 F). The shells also protect the RNA during the first step of the PCR and LAMP tests, which involves breaking down cells in the sample—via enzymes or heat—to release their genetic material for testing.

These protections are not present in the positive controls currently used in COVID-19 testing (naked synthetic RNAs, plasmids or RNA samples from infected patients). That’s why existing controls either require refrigeration (which makes them inconvenient to handle, costly to ship and store) or have to be added at a later stage of the test (which means that means scientists will not know if something went wrong in the first steps).

As a next step, the researchers are looking to partner up with industry to implement this technology. The positive controls can be adapted to any established RT-PCR or RT-LAMP assay, and using them would help negate false readouts, Steinmetz’s team said. Plus, these positive controls can be easily produced in large quantities by molecular farming in plants or microbial culture fermentation, which is good news for translating them to large-scale manufacturing.

Source: Read Full Article