insights from industryFang-Yi ChuTechnical Account ManagerSino Biological

insights from industryFang-Yi ChuTechnical Account ManagerSino BiologicalIn this interview, Dr. Fang-Yi Chu talks to NewsMedical about the role of transmembrane proteins in targeting oncology research.

Can you explain what transmembrane proteins are and why they are important?

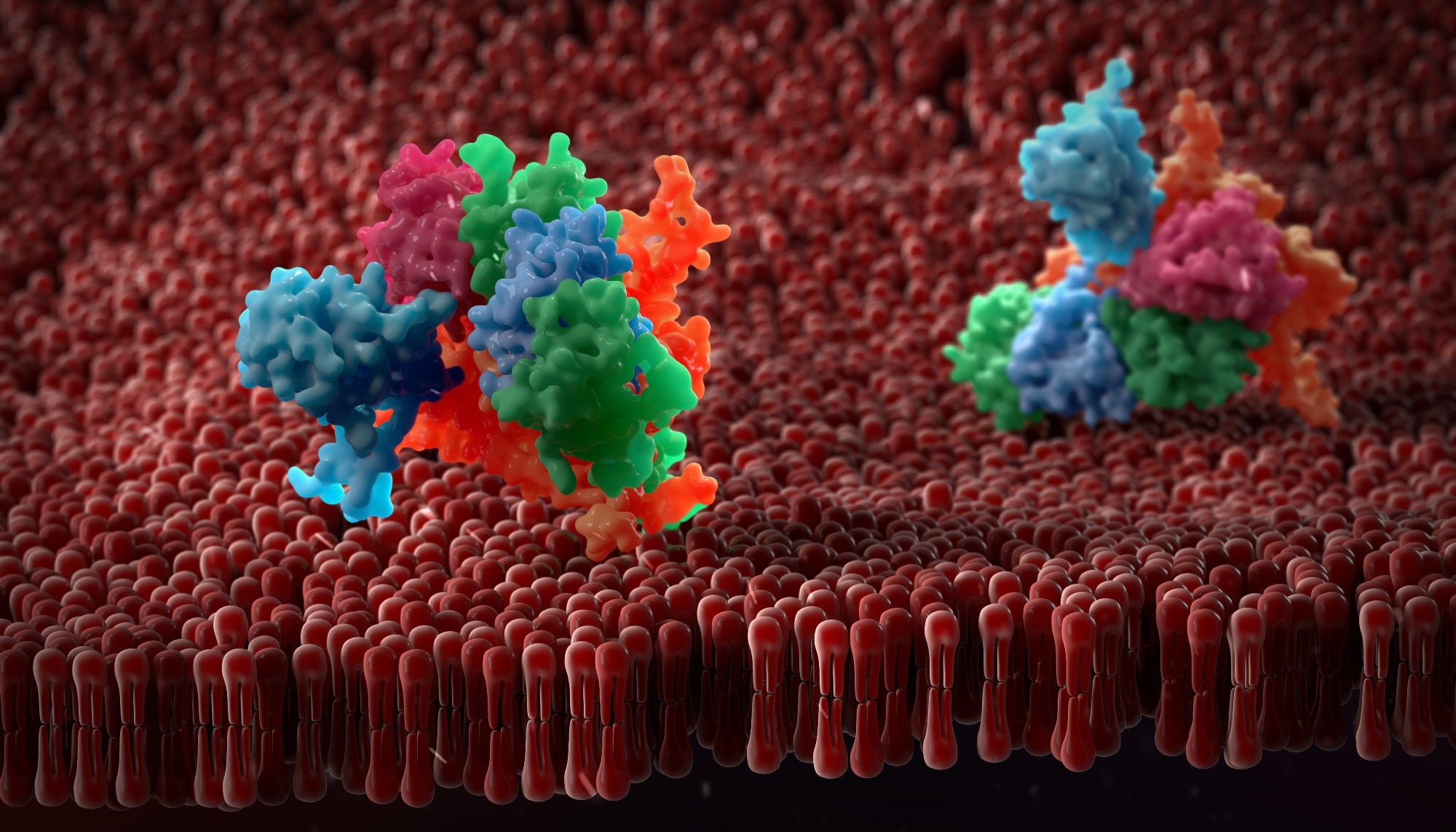

Transmembrane proteins play a crucial role in cellular function by residing in the lipid bilayer of cell membranes, which separates the cell interior from the external environment.

These proteins are diverse and are involved in a myriad of cellular processes, including signal transduction, cell adhesion, and cell-to-cell interactions.

The significance of transmembrane proteins lies in their control over the movement of substances in and out of cells, influencing cellular processes from signal transduction to immune response modulation.

Approximately 70-80% of membrane proteins are integral, meaning they are permanently attached to the biological membrane.

They can be classified into different types, including alpha-helical anchor proteins and transmembrane proteins with hydrophobic regions embedded in the membrane.

Watch the Webinar

Watch the WebinarCan you provide some specific applications or advancements in oncology research facilitated by transmembrane proteins?

Transmembrane proteins play a crucial role in advancing oncology research by serving as key targets for therapeutic interventions.

One notable application is in the development of targeted cancer therapies, where transmembrane proteins, such as G-protein-coupled receptors (GPCRs), are explored as potential drug targets.

GPCRs, for instance, are involved in various physiological processes and have been implicated in diseases like cancer.

By understanding the structure and function of transmembrane proteins, researchers can design small molecule drugs that specifically target these proteins, influencing cellular processes related to cancer progression.

Additionally, the production of transmembrane proteins using innovative platforms provides a foundation for studying their interactions with other molecules, aiding in the design and validation of novel cancer drugs.

What challenges are associated with producing transmembrane proteins, and how do Sino Biological's platforms address these challenges?

Producing transmembrane proteins poses several challenges, primarily due to their hydrophobic nature, tissue-specific expression, and susceptibility to aggregation.

These proteins are not soluble without detergents or lipids, and their expression can be tissue-specific, potentially causing cell damage and leading to low yields.

Extraction from tissues may result in low efficiency, and purification processes can be complicated.

Furthermore, transmembrane proteins are inherently difficult to maintain in their native conformation and are prone to aggregation. Sino Biological addresses these challenges through three innovative platforms.

Image Credit: urfin/Shutterstock.com

Can you provide an overview of the three platforms for transmembrane protein production that Sino Biological has established?

At Sino Biological, we have developed three robust platforms for transmembrane protein production.

The first platform involves Virus-Like Particles (VLPs), nanoscale particles composed of viral capsid proteins and cell membrane components.

These VLPs, approximately 100 to 300 nanometers in diameter, display transmembrane proteins in their native conformation, making them ideal for immunization and antibody screening.

The second platform utilizes detergent micelles, employing detergents to solubilize transmembrane proteins by disrupting hydrophobic associations and destroying lipid bilayers.

The third platform, Nanodiscs, is created using either styrene maleic anhydride (SMA) or membrane scaffold proteins (MSP) to maintain native lipid environments.

SMA inserts into cell membranes, while MSP involves transient solubilization with detergent and subsequent assembly with phospholipids. Nanodiscs allow for the study of protein-lipid interactions.

Each platform has its strengths, with VLPs offering speed, Detergent Micelles providing purity, and Nanodiscs combining a native-like environment with flexibility in design.

Can you provide some example case studies where these transmembrane proteins were validated using different platforms?

In our case studies, we have successfully validated transmembrane proteins using three distinct platforms: virus-like particles (VLP), detergent micelle, and nanodiscs.

For instance, we focused on GPRC5D, a G-protein-coupled receptor highly expressed on CD138+ multiple myeloma cells. The VLP product was validated through ELISA and Western blots, demonstrating high batch-to-batch consistency and efficacy in antibody generation.

The detergent version, solubilized using SMA, underwent validation through ELISA and bio-layer interferometry (BLI) with an affinity constant (KD) of approximately 58 nanometers.

Moving to nanodiscs, we employed SMA polymers and membrane scaffold protein (MSP) to create nanodiscs for GPRC5D.

These nanodiscs exhibited binding in ELISA, BLI, and surface plasmon resonance (SPR) with an impressive KD as low as 0.7 nanometers, showcasing the effectiveness of our nanodisc platform.

In another case study, we explored claudin proteins, specifically claudin 5, claudin 6, and claudin 18.2, validating their VLP and detergent versions through ELISA.

Nanodiscs for these proteins showed a KD as slow as 0.5 nanometers, reinforcing the success of our nanodisc platform across different transmembrane proteins.

These case studies underscore the versatility and reliability of our diverse protein production platforms at Sino Biological.

How does Sino Biological approach the production and purification of bispecific antibodies, and what are the key considerations in this process?

At Sino Biological, our approach to the production and purification of bispecific antibodies involves a comprehensive and flexible strategy tailored to meet the diverse needs of our clients.

We begin with gene synthesis and cloning, followed by transient transfection of the plasmid into the HEK293 system for expression.

After a 5 to 7-day expression period, we harvest and break down the cells to extract the membrane and solubilize the transmembrane protein using various platforms such as virus-like particles (VLP), detergent micelles, and nanodiscs.

For the purification process, we employ different tests based on the chosen platform.

In the case of bispecific antibodies, we have expertise in over 14 bispecific antibody formats, with common ones including DutaMab, IgG-scFv, and BiTE.

We have achieved a remarkable success rate of over 90% in more than 80 projects, and our bispecific antibodies undergo validation through cell-based assays and techniques like surface plasmon resonance (SPR) or bio-layer interferometry (BLI).

Our purification protocols ensure high purity, with yields reaching up to 250 milligrams per liter. We prioritize client flexibility and can adapt our procedures based on specific needs, providing a reliable and high-quality solution for the production of bispecific antibodies.

What are the advantages of the recombinant technology used by Sino Biological in antibody production, and how does it differ from traditional methods?

The recombinant technology employed by Sino Biological in antibody production offers several distinct advantages over traditional methods. One key advantage lies in the ability to produce a large number of antibodies simultaneously, thanks to the high-throughput capabilities of the recombinant technology.

With up to 1500 liters of bioreactors, Sino Biological can achieve kilogram-level production, demonstrating scalability for large-scale antibody manufacturing. Additionally, the in-house development of all reagents ensures quality control and the availability of diverse expression systems, including those for human, mouse, rat, and rabbit antibodies.

This flexibility allows Sino Biological to cater to various research needs. The recombinant production approach also facilitates the production of different antibody formats, such as IgG, IgM, and IgA, as well as fragments like scFv and Fab antibodies.

Could you provide more details about Sino Biological's new production site, the Center of BioProcessing, and how it will enhance your services?

The Center of BioProcessing in Houston marks an exciting expansion for Sino Biological, allowing us to further elevate our services. This new production site is strategically positioned to enhance efficiency, offering a local hub for our operations.

With a warehouse in Pennsylvania for US stocks and an office in Texas, the addition of the Center of BioProcessing will bring us even closer to our clients, facilitating faster turnaround times and streamlined communication.

This local presence aligns with our commitment to providing top-notch reagent and CRO services. The state-of-the-art facility is poised to bolster our capabilities in protein expression, antibody development, and customized assay development.

How does Sino Biological envision its contributions to scientific and human health fields, and what impact do you hope to achieve through your products and services?

Sino Biological envisions playing a pivotal role in advancing scientific understanding and improving human health through its comprehensive range of products and services.

Our commitment extends beyond being a leading reagent provider and contract research organization; we aim to be a catalyst for groundbreaking discoveries and advancements.

By offering over 6,500 proteins, 14,000 antibodies, 47,000 genes, and 600 ELISA kits, we empower researchers worldwide with the tools they need for innovative studies.

Our focus on transmembrane protein production, showcased through three established platforms, demonstrates our dedication to addressing challenging areas in biology and medicine.

Through our contributions to antibody development, customized assay development, and high-impact research projects, we aspire to accelerate progress in diverse fields such as oncology, immunotherapy, and drug development.

As we expand globally, with new production facilities and strategic locations, we aim to enhance accessibility, communication, and service efficiency, ultimately contributing to the scientific community's ability to make lasting positive impacts on human health.

About Fang-Yi Chu

Dr. Fang-Yi Chu is a Technical Account Manager at Sino Biological. She is in charge of the customized services, including protein expression, antibody development, and bioassays.

Before joining Sino Biological, Dr. Chu obtained her Ph.D. degree in Physics from New York University. After graduation, she did her post-doctoral training at the University of Pennsylvania.

Dr. Chu’s fields of expertise include biophysics, bioengineering, and soft matter.

About Sino Biological Inc.

Sino Biological is an international reagent supplier and service provider. The company specializes in recombinant protein production and antibody development. All of Sino Biological's products are independently developed and produced, including recombinant proteins, antibodies and cDNA clones. Sino Biological is the researchers' one-stop technical services shop for the advanced technology platforms they need to make advancements. In addition, Sino Biological offers pharmaceutical companies and biotechnology firms pre-clinical production technology services for hundreds of monoclonal antibody drug candidates.

Sino Biological's core business

Sino Biological is committed to providing high-quality recombinant protein and antibody reagents and to being a one-stop technical services shop for life science researchers around the world. All of our products are independently developed and produced. In addition, we offer pharmaceutical companies and biotechnology firms pre-clinical production technology services for hundreds of monoclonal antibody drug candidates. Our product quality control indicators meet rigorous requirements for clinical use samples. It takes only a few weeks for us to produce 1 to 30 grams of purified monoclonal antibody from gene sequencing.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.